United Arab Emirates (UAE) Crown Prince Mohammed bin Zayed al-Nahyan's key aide arrived in Seoul, Monday, amid high hopes that his visit will contain allegations about a possible rift in bilateral nuclear cooperation and economic relations.

The visit by Khaldoon Khalifa Al Mubarak, chairman of the Executive Affairs Authority of Abu Dhabi, comes about a month after Im Jong-seok, presidential chief of staff, visited the Middle East country in December.

Al Mubarak is one of the closest aides to the UAE crown prince. He was present at meeting with Im.

During his high-profile two-day visit, the UAE official is expected to pay a courtesy call on President Moon Jae-in in an apparent bid to address speculation about a bilateral feud. The government is expected to explain the results of the meeting to the press afterward.

Im's visit to the UAE, which Cheong Wa Dae claimed was aimed at boosting the morale of Korean soldiers stationed there and enhancing bilateral relations, has caused speculations that his mission was to handle complaints from the UAE.The opposition bloc claimed that the visit might have been aimed at mitigating the UAE's concerns over the possible impact of President Moon's nuclear phase-out policy on a $40 billion bilateral deal. Under the deal, signed in 2009 under the Lee Myung-bak government, Seoul was to build and operate four nuclear reactors in the Middle Eastern country.

Eyes are on whether the visit of Al Mubarak will be able to remove various allegations about bilateral relations.

The speculation includes Seoul's alleged move to withdraw Korean troops from the UAE in an effort to revise what the Moon government believes were the "secret" mutual military agreements signed under the Lee government in return for the 2009 nuclear contract.

Another speculation being raised is that Korean firms have had difficulty running projects in the UAE as a result of a protest from the Middle Eastern country. This speculation seemed to pick up steam by the fact Im met with SK Group Chairman Chey Tae-won before leaving for the UAE in December.

Defense Minister Song Young-moo has reportedly explained to politicians that the UAE has raised questions over the Moon government's move to revise a memorandum of understanding signed under the Lee government. Song also visited the UAE in early November and was believed to have delivered the government's position to the country.

While the main opposition Liberty Korea Party attacked the Moon government, accusing it of causing trouble in relations with the UAE while seeking politically motivated revenge on the conservative bloc, Cheong Wa Dae has failed to clear out various speculations. The government has only said it has to consider the trust between the two countries before revealing anything to the press.

However, skepticism still remains over whether the official's visit will resolve the mounting controversy as not many things are known about Al Mubarak's mission during the visit, except for his meeting with National Assembly Speaker Chung Sye-kyun, Monday.

Some sources said the UAE official may arrange Moon's possible visit to the UAE, given the President told the crown prince during phone talks in June that he hoped to attend the ceremony to mark the completion of a nuclear reactor in the UAE.

|

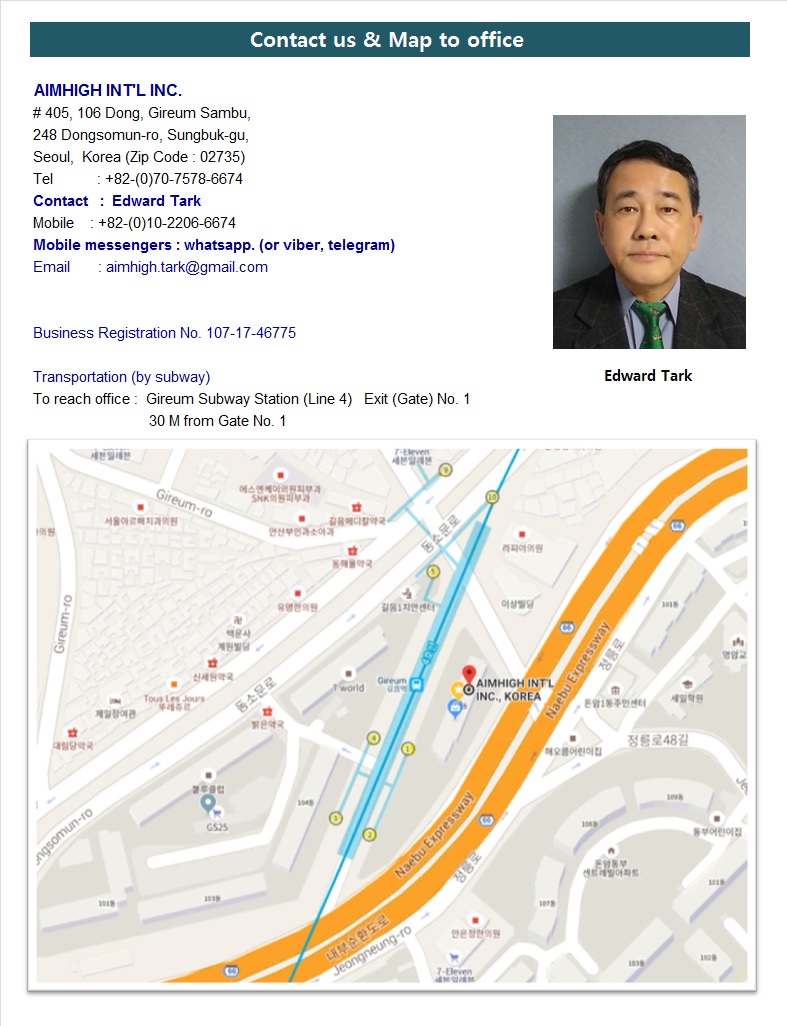

| Khaldoon Khalifa Al Mubarak, a key aide to United Arab Emirates Crown Prince Mohammed bin Zayed al-Nahyan, and the chairman of the Executive Affairs Authority of Abu Dhabi, arrives at the National Assembly, Monday, for a meeting with Assembly Speaker Chung Sye- |

Al Mubarak is one of the closest aides to the UAE crown prince. He was present at meeting with Im.

During his high-profile two-day visit, the UAE official is expected to pay a courtesy call on President Moon Jae-in in an apparent bid to address speculation about a bilateral feud. The government is expected to explain the results of the meeting to the press afterward.

Im's visit to the UAE, which Cheong Wa Dae claimed was aimed at boosting the morale of Korean soldiers stationed there and enhancing bilateral relations, has caused speculations that his mission was to handle complaints from the UAE.The opposition bloc claimed that the visit might have been aimed at mitigating the UAE's concerns over the possible impact of President Moon's nuclear phase-out policy on a $40 billion bilateral deal. Under the deal, signed in 2009 under the Lee Myung-bak government, Seoul was to build and operate four nuclear reactors in the Middle Eastern country.

Eyes are on whether the visit of Al Mubarak will be able to remove various allegations about bilateral relations.

|

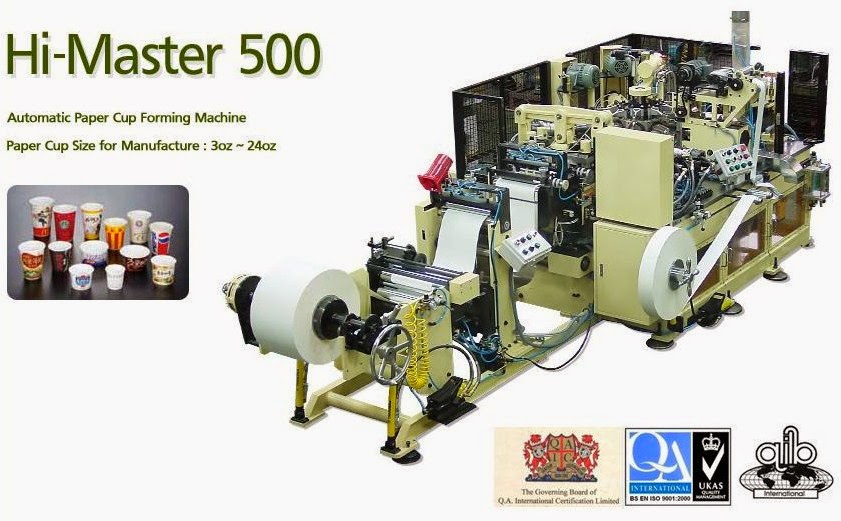

| President Moon Jae-in and his chief of staff Im Jong-seok attend a meeting at Cheong Wa Dae, Monday. / Yonhap |

Another speculation being raised is that Korean firms have had difficulty running projects in the UAE as a result of a protest from the Middle Eastern country. This speculation seemed to pick up steam by the fact Im met with SK Group Chairman Chey Tae-won before leaving for the UAE in December.

Defense Minister Song Young-moo has reportedly explained to politicians that the UAE has raised questions over the Moon government's move to revise a memorandum of understanding signed under the Lee government. Song also visited the UAE in early November and was believed to have delivered the government's position to the country.

While the main opposition Liberty Korea Party attacked the Moon government, accusing it of causing trouble in relations with the UAE while seeking politically motivated revenge on the conservative bloc, Cheong Wa Dae has failed to clear out various speculations. The government has only said it has to consider the trust between the two countries before revealing anything to the press.

However, skepticism still remains over whether the official's visit will resolve the mounting controversy as not many things are known about Al Mubarak's mission during the visit, except for his meeting with National Assembly Speaker Chung Sye-kyun, Monday.

Some sources said the UAE official may arrange Moon's possible visit to the UAE, given the President told the crown prince during phone talks in June that he hoped to attend the ceremony to mark the completion of a nuclear reactor in the UAE.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)